Quality Steel Fittings in Melbourne – Durable & Affordable Solutions

Melbourne plays a key role in Australia’s manufacturing and construction sectors. Steel fittings form an integral part of these industries, supporting applications that range from residential plumbing to large-scale industrial and infrastructure projects. The city’s continued growth and investment in long-lasting construction increase demand for materials that withstand heavy use and environmental exposure.

Local suppliers offer an extensive range of steel fittings tailored to the requirements of builders, contractors, engineers, and tradespeople. These products directly affect the performance and safety of piping and structural systems. Professionals working in construction and maintenance rely on durable fittings to achieve stable installations, smooth operation, and consistent outcomes across all types of projects. Understanding the function and quality of these components helps businesses maintain efficiency and dependability.

Understanding Steel Fittings

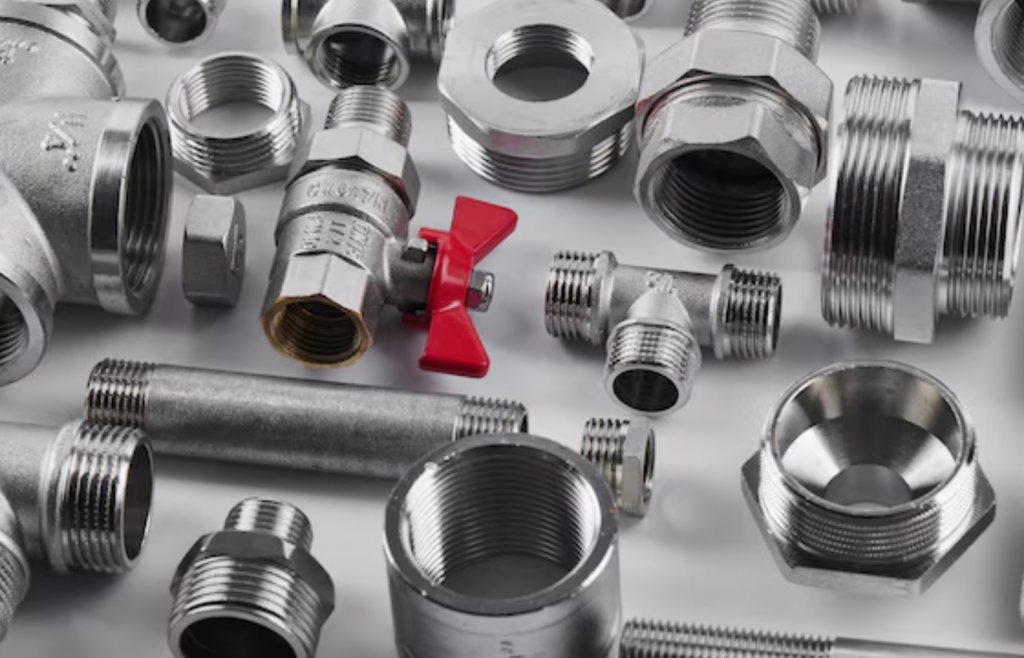

Steel fittings Melbourne products are designed to connect, terminate, or manage piping systems. They are produced in various shapes and dimensions to provide strength, longevity, and functional reliability. Correctly chosen fittings help maintain efficient flow, structural stability, and operational safety.

Common fittings include elbows, tees, reducers, and flanges. Each type addresses a specific need, such as redirecting flow, connecting pipes of different diameters, or forming secure joints. In construction and industrial contexts, these components support operational efficiency, maintain structural integrity, and prevent failures that could disrupt projects or compromise safety. Professionals depend on these materials to complete work with precision and consistency, minimising downtime and extending the life of systems.

Quality Standards and Material Performance

The quality of steel used in fittings is measured through assessments of strength, hardness, ductility, and impact resistance. These factors determine how well components perform under stress and affect the durability of entire systems. High-grade steel reduces the frequency of maintenance, protects against damage, and sustains performance over long periods.

Steel fittings that meet recognised standards offer dependable results in industrial, commercial, and residential applications. Australian and international guidelines provide benchmarks that guarantee structural integrity and reliability. Using certified materials ensures that installations perform safely and meet regulatory requirements. This approach safeguards investments and contributes to the long-term success of construction projects.

Rising Demand for Steel Fittings in Melbourne

Melbourne’s ongoing urban development and infrastructure initiatives generate strong demand for high-quality steel fittings. Builders and contractors increasingly require materials capable of supporting structures designed to endure daily wear and environmental stresses. Durable fittings are particularly valuable for projects focused on safety and longevity, including pipelines, bridges, and commercial buildings.

Suppliers in the city respond by providing a diverse range of fittings that balance performance and affordability. Access to a wide selection of components allows professionals to manage projects efficiently while keeping costs manageable. Reliable fittings reduce the risk of unexpected failures and support a smoother construction process, contributing to overall project stability.

Durability and Cost Considerations

Steel fittings produced with careful material selection and precision manufacturing deliver consistent performance over time. Their resistance to corrosion and wear allows them to operate effectively in demanding conditions. These properties make them suitable for both everyday applications and high-stress industrial environments.

Obtaining cost-effective solutions is achievable through thoughtful planning and supplier comparison. Investing in products that maintain their integrity over time can lower long-term expenses, preventing frequent replacements or repairs. Contractors and project managers benefit from the combination of quality and practicality, achieving project goals without compromising performance or exceeding budgets.

Guidance for Selecting Steel Fittings

When acquiring steel fittings, attention to material strength, compatibility with existing systems, and pressure ratings is necessary. The reputation of manufacturers, product testing, and verified certifications contribute to reliable installations. Accurate sizing and careful verification of specifications help maintain operational performance and avoid delays during implementation.

Evaluating suppliers based on reliability, cost, and product quality allows buyers to make informed choices. Strategic purchasing supports project efficiency, maintains safety standards, and strengthens the durability of installations. Planning purchases with a focus on long-term use ensures that materials continue to provide value and performance well beyond the completion of initial construction work.

Conclusion

Steel fittings are a foundational element in Melbourne’s construction, industrial, and maintenance activities. Their reliability, strength, and affordability have a direct impact on the success of projects ranging from residential renovations to large-scale infrastructure. Access to high-quality fittings allows contractors, engineers, and builders to achieve consistent results, maintain safe operations, and extend the life of installations.

Selecting well-manufactured steel fittings represents a practical investment for those responsible for construction and maintenance in Melbourne. Careful assessment of material properties, compatibility with systems, and supplier reputation supports confident project execution. Reliable steel fittings provide the stability and longevity needed for high-performing structures, making them an indispensable component of effective construction and industrial operations.